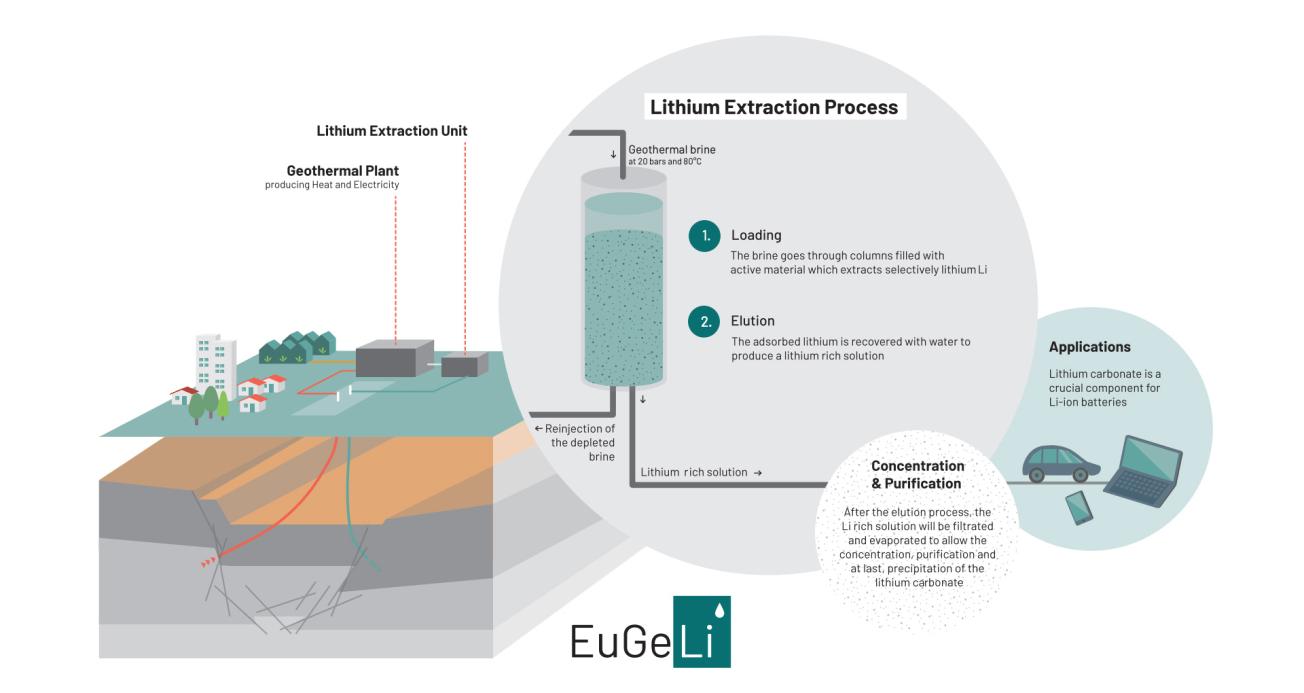

Diagram of the process for extracting lithium from geothermal brines.

© Eramet

The need

The EuGeLi (European Geothermal Lithium Brine) project, funded by the European Institute of Innovation and Technology, Raw Materials section (EIT Raw Materials), aimed to develop an industrial-scale process for the co-production of lithium and energy from geothermal brines in the Rhine Gaben.

In the context of energy transition, lithium is a metal which is attracting considerable interest, particularly for the production of batteries for electric vehicles, for which worldwide demand continues to increase, while the main suppliers of the metal today are Latin America, Australia and China.

In this context, there is a need to establish a European industry for producing lithium from unconventional sources. This is the ambitious goal of the EuGeLi project coordinated by the French group ERAMET in collaboration with eight other partners from France, Germany and Belgium. The project began in January 2019 and was completed in December 2021 (over a period of three years).

The results

The EuGeLi project aimed to develop battery-grade lithium production from geothermal brines located on the French-German border. The region is an important reservoir for such brines, which are currently being exploited for power and heat generation. The brines are mostly enriched in lithium because of subsurface water-rock interactions. They are an untapped lithium resource in Europe, which could be usefully exploited.

ERAMET and IFPEN have developed an innovative process for extracting lithium from geothermal brines. This process uses extraction columns filled with an adsorbent which selectively removes the lithium from the brine. The project’s objective was to extract lithium from subsurface water and to inject the latter back below the ground while also making use of the geothermal potential.

The EuGeLi project ended with a successful achievement: the first kilograms of battery-grade lithium carbonate were produced from European geothermal water. This was the first time ever. The lithium contained in this water was extracted directly at medium temperature and under pressure at the active Soultz-sous-Forêts (Bas-Rhin) site.

The Soultz-sous-Forêts site in Bas-Rhin, France.

© BRGM - Albert Genter

Using the results

The technical objectives of the project were achieved. The next steps will be to optimise the economic model in order to assess whether it would be possible to set up a competitive lithium production scheme for batteries on an industrial scale, as a complement to renewable energy, all made in France and without CO2.

The EuGeLi project’s outcomes will be:

- to create a European, sustainable, long-term lithium supply and boost the development of end-use applications, such as in lithium batteries (a high-growth market) and the ceramics industry,

- and in addition, to significantly reduce the environmental footprint of industrial lithium production plants thanks to this alternative process.

BRGM’s role

BRGM’s role as part of the EuGeLi project is specifically:

- to make an inventory of the resource, including a database and geostatistical analyses and maps of geothermal brines in Europe. This inventory will improve our knowledge of what causes lithium enrichment and will compile data for approximately one hundred brine samples with a lithium concentration above 90 mg/L, incorporating about 100 parameters, including temperature, flow rate and composition: major or trace elements or their isotopes.

- to model the geochemical process and define key control parameters using laboratory and in situ testing.

- to monitor on-site pilot trials by chemical/isotopic analyses.

The partners

- ERAMET (Coordinator)

- ES - Electricité de Strasbourg

- IFP Energies Nouvelles

- Chimie Paris Tech.

- BASF

- Eifer

- VITO

- VUB - Vrije Universiteit Brussel